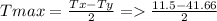

Missing Diagram is attached.

Answer:

a) 21.43 MPa

b) -14.2 MPa

Step-by-step explanation:

Given:

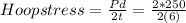

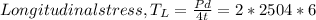

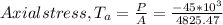

Calculating the stresses:

= 41.667 MPa

= 20.833 MPa

-9.325 MPa

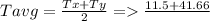

For stress along x axis:

Tx = Tl - Ta

= 20.83 - 9.325

= 11.5 MPa

= 26.58 MPa

= -15.08 MPa

Mohr's circle angle = 2∅

= 2 * 35°

= 70°

a) for normal stress perpendicular to weld, we have:

Tx' = Tavg + Tmax (cos70°}

= 26.590 - 15.08(cos70°)

= 21.43 MPa

b) shearing stress parallel to weld:

= Tmax (sin70°}

= -15.08 sin70°

= -14.2 MPa