(a) To determine the average hourly production rate, we need to calculate the total number of units produced per hour.

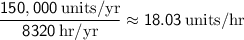

Total units produced per year: 150,000 units/yr

Total hours per year: 8 hr/shift × 2 shifts/day × 5 days/wk × 52 wk/yr = 8320 hr/yr

Average hourly production rate:

Therefore, the average hourly production rate is approximately 18.03 units/hr.

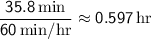

(b) To calculate the cycle time, we need to convert the work content time to hours and divide it by the proportion uptime.

Work content time: 35.8 min =

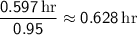

Cycle time:

Therefore, the cycle time is approximately 0.628 hr.

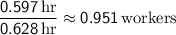

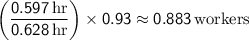

(c) The theoretical minimum number of workers required on the line can be calculated by dividing the work content time by the cycle time.

Theoretical minimum number of workers:

Since we can't have fractional workers, the theoretical minimum number of workers required on the line would be 1 worker.

(d) To calculate the actual number of workers required, we need to consider the balance efficiency and the repositioning time. We'll divide the work content time by the cycle time multiplied by the balance efficiency.

Actual number of workers required:

Again, we can't have fractional workers, so the actual number of workers required would be 1 worker.

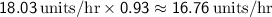

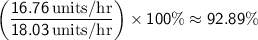

(e) The assembly line labor efficiency can be calculated by dividing the actual hourly production rate (taking into account the balance efficiency and repositioning time) by the average hourly production rate.

Actual hourly production rate:

Assembly line labor efficiency:

Therefore, the assembly line labor efficiency is approximately 92.89%.